Clean Room Project

Product Details:

X

Clean Room Project Price And Quantity

- 1 , , Unit

Clean Room Project Trade Information

- Noida

- 10 , , Unit Per Month

- 8-10 Week

- Yes

- Contact us for information regarding our sample policy

- Standard Packaging

- All India

- ISO 9001:2015

Product Description

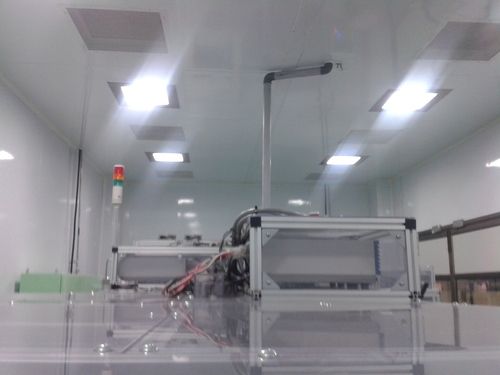

Under our clean room project, our team designs and develops clean room in custom specifications. Small particles can adversely affect the manufacturing process, where clean room is required practically in every industry. The size and complexity of a clean room can vary, and it is utilized in many industries including pharmaceuticals, medical device manufacturing, aerospace and other. Generally, a cleanroom is an enclosed space where particulate contamination is reduced and other environmental parameters are controlled. One of the most important components is its filter, which is used to trap small to large particles.

Specification

|

Brand |

Sam Products |

|

Color |

Customized |

|

Size |

Customized |

|

Project Duration |

1-2 weeks |

|

Business / Industry Type |

Manufacturing |

|

Type of Service Provider |

Company |

|

Mode of Service |

Offline |

Customizable Modular Clean Room Solutions

Our clean room systems offer modularity, enabling tailored configurations to meet specific project sizes and industry requirements. From panel thickness and ceiling construction to flooring and door types, you can customize every aspect for optimal workflow, accessibility, and regulatory compliance.

Superior Air Filtration and Controlled Environment

Engineered to ISO Class 5-8 standards, these clean rooms maintain strict air purity and environmental stability. Positive or negative pressure, humidity control up to 60% RH, and temperature regulation between 18C and 26C ensure product integrity for sensitive manufacturing and research processes.

Energy-Efficient and Safe Construction

Constructed with Class A, flame-retardant panels and low-glare LED lighting, these clean rooms prioritize safety and sustainability. The energy-saving features and water-repellent materials further enhance operational efficiency while adhering to stringent safety and hygiene protocols.

FAQ's of Clean Room Project:

Q: How is the air quality maintained in these clean rooms?

A: The clean rooms utilize advanced air filtration systems conforming to ISO Class 5 to Class 8 standards, ensuring removal of airborne contaminants. Positive or negative pressure environments are managed for consistent cleanliness and safety.Q: What customization options are available for panel thickness and room size?

A: Panel thickness can be specified at 50mm or 100mm, and the maximum clean room size is fully customizable to align with project requirements for different industries and applications.Q: When should I choose walkable versus non-walkable ceiling construction?

A: Walkable ceilings are recommended when maintenance access above the clean room is needed, such as for HVAC or lighting servicing. Non-walkable ceilings are ideal for areas with limited overhead access needs.Q: Where can these clean rooms be used effectively?

A: These clean rooms are suitable for applications in pharmaceuticals, hospitals, laboratories, semiconductor manufacturing, and food processing industries-anyplace requiring strict environmental control and contamination prevention.Q: What is the process for installing a modular clean room system?

A: Installation involves planning the layout and selecting custom features like panel thickness, flooring, doors, ceiling type, and lighting. Prefabricated modules are then assembled onsite to minimize downtime and ensure rapid deployment.Q: How do the energy-saving and water-repellent features benefit users?

A: Energy-efficient lighting, insulated panels, and water-repellent materials reduce utility costs, enhance safety, manage humidity, and maintain optimal cleanliness, making operations both sustainable and reliable.Q: What types of flooring and doors can be selected for these clean rooms?

A: Flooring is available in epoxy, vinyl, or anti-static finishes to match application needs. Door options include swing, sliding, or automatic doors, each designed to maintain air tightness and ease of access.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email