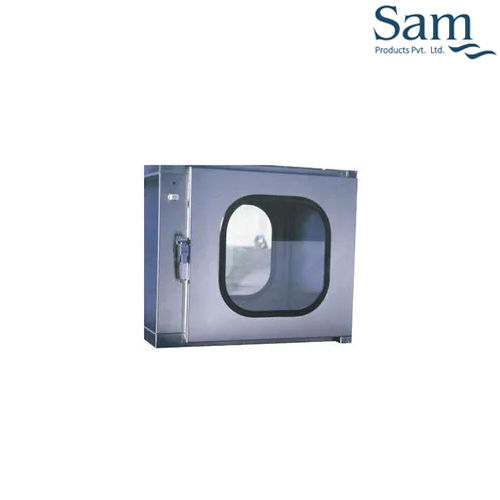

Clean Room Pass Box

Product Details:

- Material Stainless Steel (SS 304)

- Filter Type HEPA, 99.99% at 0.3 micron

- Door Double Door with Electromagnetic Interlock

- Filters HEPA Filter

- Voltage 220V / 50Hz

- Air Flow Horizontal

- Weight 45 kg

- Click to View more

X

Clean Room Pass Box Price And Quantity

- 1 Piece

Clean Room Pass Box Product Specifications

- Stainless Steel Jet Nozzle

- Static and Dynamic

- Stainless Steel

- Pharmaceutical, Laboratory, Cleanroom

- UV Lamp, Indicator, Easy to Clean

- 40W

- 1.2 mm to 1.5 mm

- 350 m3/h

- Double Door with Electromagnetic Interlock

- Stainless Steel (SS 304)

- HEPA, 99.99% at 0.3 micron

- Horizontal

- 220V / 50Hz

- HEPA Filter

- New

- 600mm x 600mm x 600mm

- 45 kg

- LED Light

- Stainless Steel Base Plate

Clean Room Pass Box Trade Information

- Noida - Uttar Pradesh

- 10 Piece Per Month

- 1 Week

- Yes

- Contact us for information regarding our sample policy

- Standard Packaging

- Uttar Pradesh

- ISO 9001:2015

Product Description

This is placed on the walls of the room between classified area & non-classified area. It is used for transferring o material from or into the clean room without troubling its environment. This supports in averting contagion of Clean Room Pass Box, without having to open the room door thereby using interlocking of aluminum glass windows of Clean Room Pass Box. This has flexibility to suit end user requirement and capability to operate without noise and vibration. It is available in Mid Steel Sheets, Galvanized Sheets and Stainless Steels and also fabricated in Commercial Block Board with Laminates.

Size: 18" x 18" x 18", 24" x 24" x 24", 36" x 36" x 24", 48" x 48" x 24"

Precision Engineering for Maximum Contamination Control

Designed to maintain your facilitys integrity, this pass box integrates advanced filtration through a HEPA filter and an efficient UV lamp to ensure safe material transfer between rooms. Its double-door mechanism with electromagnetic interlock ensures that doors cannot be opened simultaneously, minimizing cross-contamination. The LCD digital display and microprocessor controller offer users intuitive operation and real-time monitoring, while the robust SS 304 construction and toughened glass provide durability and easy maintenance.

Seamless Integration and User-Friendly Features

Installation is versatile, with options for both floor and wall mounting. The unit comes pre-assembled with essential features such as an LED light for clear visibility, stainless steel jet nozzles for optimal air flow, and a matt or mirror finish. Service openings on both the front and back sides make it accessible for various workflow requirements. The compact design (600mm x 600mm x 600mm) fits easily into diverse cleanroom spaces, catering to the distinct needs of pharmaceutical, laboratory, and industrial applications.

FAQs of Clean Room Pass Box:

Q: How does the Clean Room Pass Box with Display help prevent contamination between cleanroom areas?

A: The pass box utilizes a double-door electromagnetic interlock system, ensuring only one door is open at a time, and incorporates HEPA filtration (99.99% at 0.3 microns) alongside UV lamp sterilization to provide a safe passage for materials while minimizing the risk of cross-contamination.Q: What is the process for operating the pass box, and how is it monitored?

A: Operation is managed through a microprocessor-based controller and LCD digital display, providing clear status indications. The user places materials inside, closes the door, and can monitor door status and internal conditions. The controller ensures proper interlocking, and an alarm signals if a door remains open.Q: When should the HEPA filter and UV lamp be serviced or replaced?

A: HEPA filters typically require inspection and replacement after extended use or when airflow decreases, often annually or as per environmental demand. The UV lamp should be replaced as per the manufacturers guidelines, generally after a defined number of operating hours for optimal sterilization efficiency.Q: Where can the pass box be installed for optimal performance?

A: This pass box can be floor or wall mounted, making it suitable for installation at entry points between different cleanroom zones or between normal and controlled environments. Its compact dimensions ensure it fits seamlessly into most facility layouts.Q: What are the main benefits of using a pass box with an LCD display and microprocessor controller?

A: The LCD display and microprocessor offer precise status updates, facilitate easy setting adjustments, and enhance operational safety with features like door open alarms and real-time parameter display, all contributing to improved workflow and compliance.Q: How does the built-in alarm system enhance safety and operational efficiency?

A: The integrated door open alarm promptly alerts users if a door is inadvertently left open, reducing contamination risks and ensuring compliance with cleanroom protocols. This feature helps maintain the required cleanroom conditions and protects sensitive processes.Q: What applications are best suited for this pass box model?

A: This pass box is ideal for pharmaceutical manufacturing, laboratory operations, and other cleanroom environments that require strict contamination control, ISO 14644 and CE certified equipment, and hygienic transfer of products or materials.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email